This Front-End Engineering Design (FEED) project involves greenfield of multiple wellhead platforms and intrafield pipeline and brownfield modifications. The corrosion works included corrosion identification and assessment, corrosion modelling, material selection and outlined of corrosion control measures, corrosion monitoring and inspection activities.

Several sensitivity studies have been performed to evaluate the chemical injection availability seeking the optimal corrosion inhibition (CI) operation. Asset integrity assessment exercises such as gap analysis, remaining life estimation, API 579 Fit-For-Service examination (Level 1 and 2) for the existing facilities were examined in order to quantify the impacts resulted by the greenfield development.

Corrosion studies and material selection were done for the CPP and 2 bridge-linked WHPs, covered the topside process and utilities, structural and instrumentation. The work involved identification of corrosion threats and damage mechanisms and candidate materials of construction in relation to the CPP facilities and to define the corrosion control philosophies in accordance to the design data made available during the Detailed Design stage. The fundamental intent is to assemble the corrosion related technical information as the basis use for input reference for the detailed design of material selection for the CPP facilities, and eventually to establish the corrosion management plan (CMP) that will be operationalized to safeguard lifelong material and asset integrity.

We have supported multidiscipline engineering during development of specifications, datasheets and subsequently during the procurement exercise, we were part of the technical evaluation team to provide material- and corrosion-related advice in TBE, TC and MOC.

The root cause was found to be presence of water within the mortar filling, should be eliminated, by formulating the cement mortar as per standard operating procedure without adding the admixture. Rectification procedures were outlined, including to remove all the mortar filling on both stiles, scrape-off the corrosion products and to reapply zinc-rich epoxy coating on the back opening prior to re-refilling with the cement mortar. UT inspection was performed post rectification to measure remaining wall thickness and metal strength, in order to ensure integrity of the door frame fits for purposes.

Premature rust stains and perforation were found on approximate 1,800 galvanised steel door frames in a housing development project. Small areas of rust stain are seen on both vertical members of the frame, perforation through the frame thickness was verified by removal of the cement mortar filling. The inner surface of the back opening revealed mixture of powdery white rust and reddish-brown porous corrosion products, evidenced the corrosion of zinc and steel respectively.

This work provides the corrosion assessment, material selection and corrosion inspection and monitoring activities to manage the risk of corrosion associated with the new onshore effluent treatment system. The corrosion mechanisms envisaged in the ETS is dictated by the presence of the constituents or corrodents within the waste streams. The wastewater stream contain chlorides, sulfides, bicarbonates, ammonia, hydrocarbons, phenol, and suspended solids. Some dissolved gases such as hydrogen sulfide, ammonia, oxygen, carbon dioxide, and volatile hydrocarbons may be desorbed during refining process depending on the type of crude oil.

The effluent streams will be dosed with several chemicals. Metallic materials such as Hastelloy, stainless steel and carbon steel are selected in accordance to the compatibility with the chemicals handled.

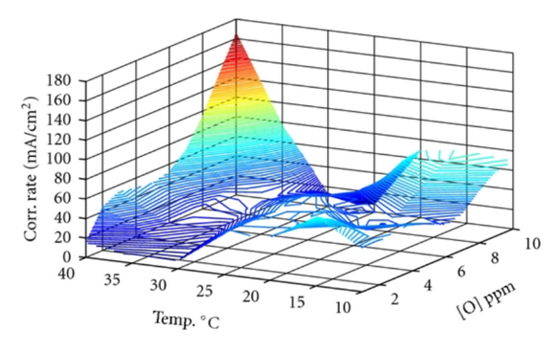

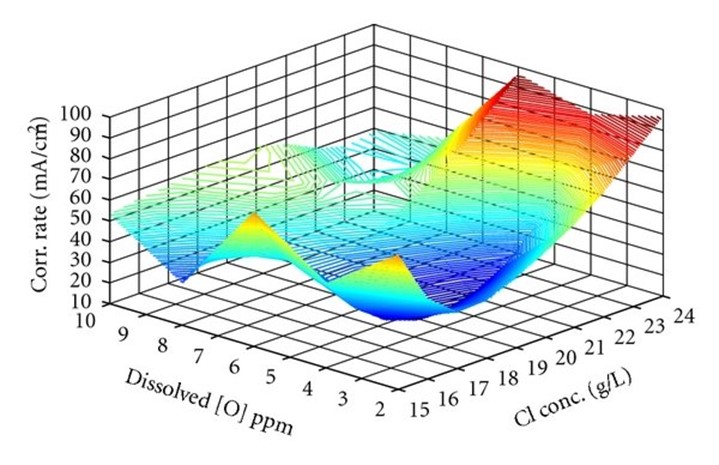

Seawater has been routinely utilized as cooling medium in offshore oil and gas production facilities; the cooling medium outlet temperature can reach up to 50 °C and this calls for corrosion resistance alloys as material selection to construct the cooling systems. We have worked on several projects involving aerated and chlorinated seawater, operates at elevated temperature >200 °C and possibly in contact with Mercury; as the operating conditions get harsher, most of the common materials of construction for seawater applications, e.g. nickel alloys, high alloyed stainless steels, are not considered feasible.

[Figure Ref] : S. Paul, Metallurgy, Vol 2012, Article 487351

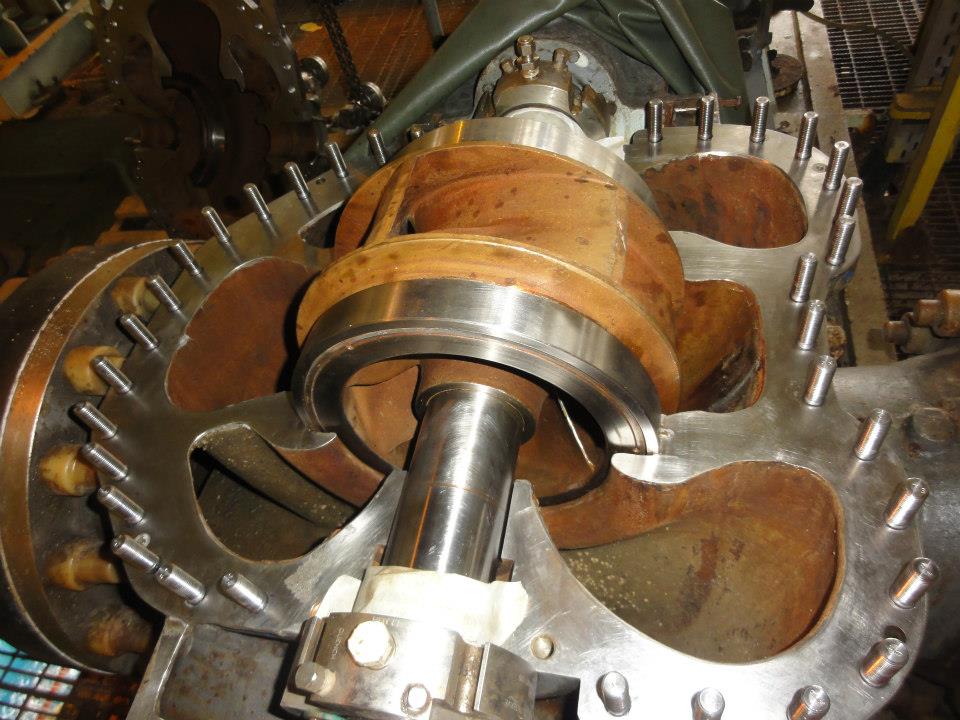

There has been limited industry experience and track records of the similar applications. However, cracking, pitting and crevice corrosion have been reported as the likely damage mechanisms when the oxide films of CRAs are breached, even more severe when the films are mechanical damaged (e.g. heavy scraped or scratched) while immersed in hot seawater, and the extent of corrosion is dependent upon alloy composition and heat treatment. Corrosion assessment was done rigorously and respective exotic alloys have been proposed, considering availability, constructability in the country and normalized cost analysis.

Reduction of FPSO vessel draft occurred as a result of lower oil production and storage in the vessel. Due to the urgency, it was decided to temporary convert the cargo oil tanks (COT) to ballast tanks by filling with treated Produced Water to meet the minimum aft draft.

3 COT tanks are specifically designed for the storage of treated crude oil containing trace amounts of water. While crude oil itself is not corrosive, water settling at the bottom of the tank or condensing in the gas-filled section at the top poses a significant risk of corrosion. Constructed from carbon steel (low alloy steel), the internal wetted surfaces of the tanks are coated at both the top and bottom sections. Additional protection is provided by a Sacrificial Anode Cathodic Protection (SACP) system, which helps mitigate corrosion. Comprehensive impact studies have been conducted to evaluate the structural integrity of the tanks and the effectiveness of the SACP system. These assessments include modeling future corrosion rates, such as general corrosion loss and microbiologically induced corrosion (MIC).

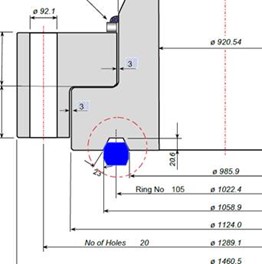

There was a concern of selecting soft iron as material of construction of the gasket for the subsea pipeline flanges (which made of low alloy steel). Inconel 625 has been requested to replace the soft iron material. This is due to the bare steel surface would be in contact with seawater during and after installation. The Figure illustrates the cross-sectional diagram of the flange groove with the gasket in place (pre-tighten), and upon installation, bulk seawater held between the gasket and the flange groove would be displaced, however, residual seawater may be trapped when the bolts and nuts are tightened.

Hence, assessment on the corrosion damages that may take place on the bare steel surface during and post-installation have been done which include the corrosivity of seawater to the gasket during tie-in activity, exposure of trapped seawater in the groove to the gasket in long term and microbial influenced corrosion (MIC) by sulphate-reducing bacteria (SRB). After considering all probable corrosion mechanisms that may occur within the microscopic voids, we observed that the extent of corrosion damage to occur is remote and insignificant. Hence, soft iron is deemed adequate and maintain as material of construction for the gasket.

This site was created with the Nicepage